How To Operate An Injection Molding Plant?Topworks Plastic Molding

Before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. In this video, you'll learn the fund.

Custom Injection Molding Rex Plastics

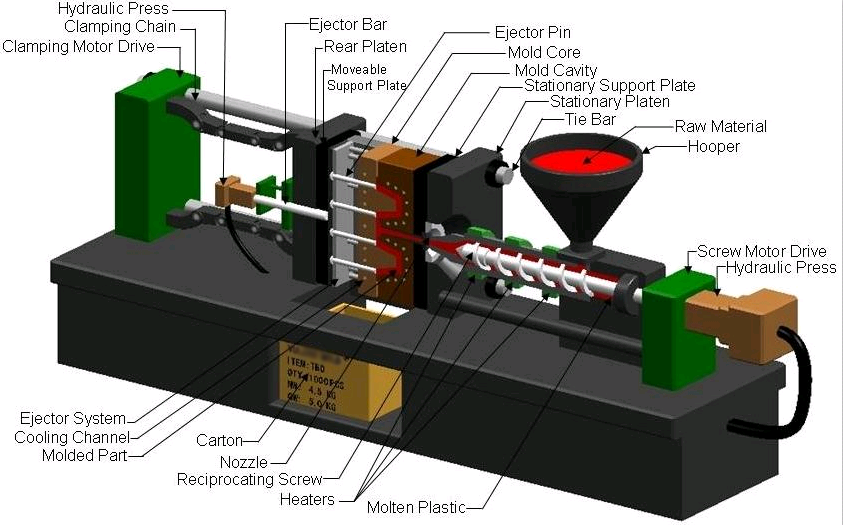

In injection molding, material is fed through a hopper into an extruder, where a reciprocating screw mixes and melts the material then injects it into a mold.. Is Your Water System Setup Helping or Hurting Your Molding Plant Productivity? The plant water system is a critical component of an injection molding facility. A poorly designed or.

Plastic Injection Molding Facility PH Molds Limited

Injection Molding Plant layout, design, and expansion: The best-looking part of a well-designed plant—The bottom line Before Duerr Inc. laid out its new building, it had a wish list built over years to start the planning. The company's best single investment? The central material handling system. Rob Neilley February 28, 2005 11 Min Read

Injection Molding Plant Items Murphy's Surplus

Low-Cost Injection Molding Leader. Pay Offshore Costs But With US Contacts. Online Quotes. Parts Shipped in as Little as 15 Days. Free Expert DfM Guidance. Large Part Capability.

Injection Molding FAQ What is Cushion & why do I need to hold it?

This vital aspect of injection molding will require the one performing the setup to follow a series of basic steps to ensure that the system is set up correctly so it can then go on to whip out those ever-so-popular products. Step 1: Reduce idling during the pre-stages of the injection mold change procedure. In the world of business, time is money.

injection_molding_factoryopt Valencia Plastics, Inc.

The process of setting up an injection molding machine is often much more than just loading and fixing the mold and pressing start. In fact, there are several key things to do after the injection mold has been clamped. This article will explore each step in the injection molding machine setup process to ensure the best-finished product possible.

ADVANCE PLASTICS Services

Assuming that the mold has already been created, injection molding becomes an easily-repeatable process consisting of six discrete steps: 1. Clamping. The first step of the injection molding process is clamping. Injection molds are typically made in two, clamshell-style pieces. In the clamping phase, the two metal plates of the mold are pushed.

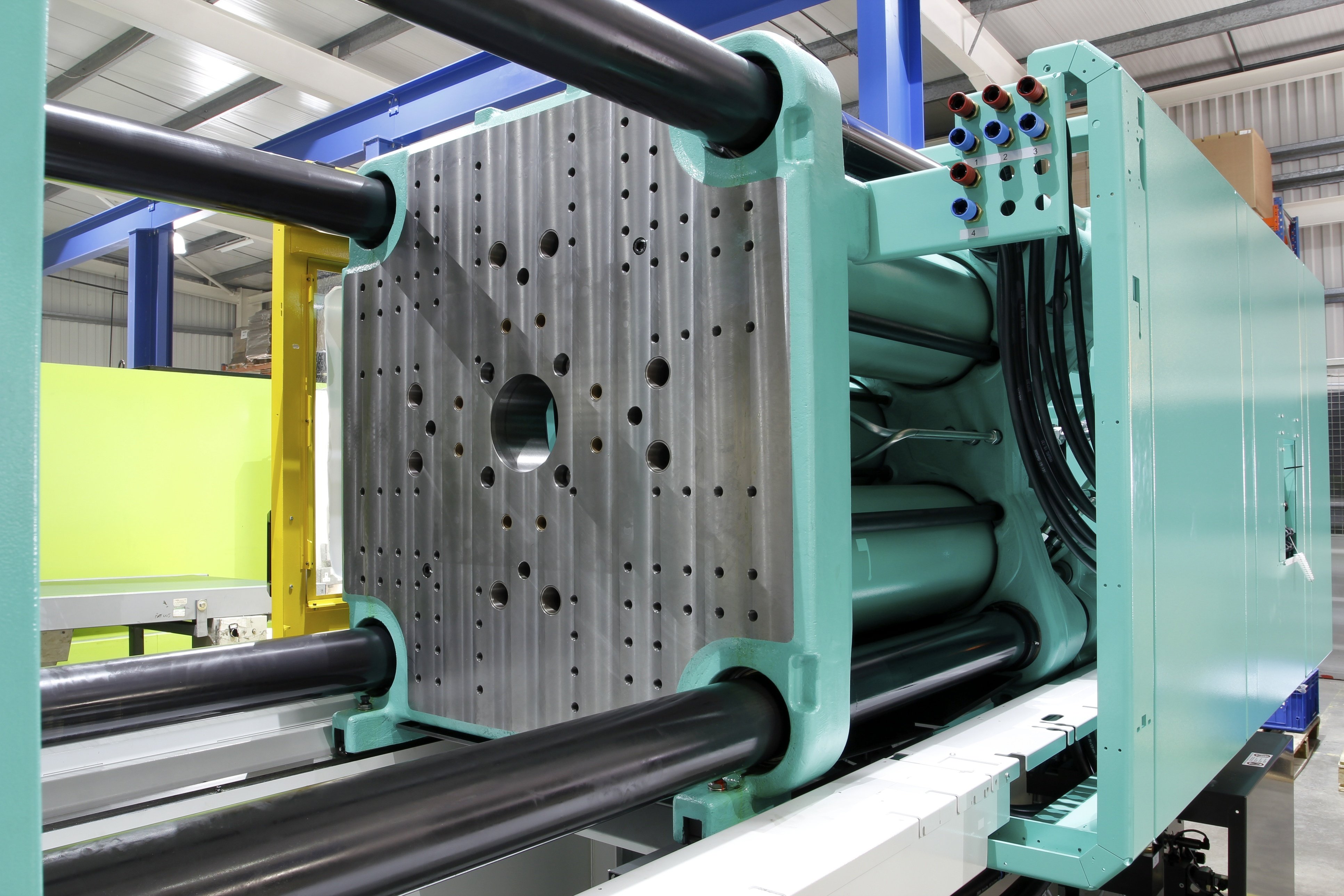

Capabilities Injection moulds and Injection moulding OMS Besser Group

Part 1 The Basics 5. What is Injection molding? 6. A brief history of Injection molding 7. Injection molding machines: How do they work? 10. Benefits & limitations of Injection molding 12. Examples of Injection molding products Part 2 Design for Injection Molding 14. Common Injection molding defects 17. Design Rules for Injection Molding 18.

Getting started Setting up an injection molding plant

The cycle time in injection molding refers to the total duration required to complete a single cycle, encompassing all the steps from mold closing to mold opening. It performs a critical function in determining the process's productivity and directly impacts customer lead times and the overall economics of the injection molding plant.

Injection Molding AGS

Because It will spend much money on all things to setup and run the factory: factory floor, equipment required (plastic injection mould, plastic injection moulding machine and other necessary machinery and tools), labor, the raw plastic required to make the product, marketing… 3. Confirm the project solution (key process to complete your plan)

Our Facilities Forum Plastics

The following is an edited excerpt from The Business of Injection Molding, by Clare Goldsberry. The book is the first title in the IMM Book Club Injection Molding Management Series, published by IMM.While much of the focus in the book is on a custom injection molding operation, many of the points about plant layout, machinery and equipment required, and staffing apply to captive molding.

Plastic Injection Molding Services

September 14, 2021 What is injection molding? Injection molding is the most widely used form of plastics processing worldwide. The process involves the injection of heated, liquefied plastic into a temperature-controlled mold under high pressure.

What is Plastic Injection Molding? Our Comprehensive Overview

1.09K subscribers Subscribe Subscribed 15K views 2 years ago CREATE INJECTION MOLDING FACTORY IN 7 MINUTES How to create basic requirement of plastic injection molding factory. What realy.

Israel Exporter Blog

Developing the production layout is the first step to review. A cell should be planned according to equipment size and height while maximizing space usage. Proper planning also should take into consideration small and large maintenance procedures. A mold change system should be developed to allow quick mold changes.

5 Processes of Making Injection Molds Techicy

In layman's terms, injection molding boils down to four simple steps: Melt material. Inject the molten material into a mold. Let the molten material cool to a solid-state. Remove the hardened material from the mold. But we can't talk about the injection molding process without discussing the injection molding machine.

SEO title preview Dầu thủy lực cho máy ép nhựa và những lưu ý sử dụng

5 Min Read When trying to establish process control in plastic injection, watering the tool is a key variable that is often overlooked. Water set-up and design are every bit as important as establishing and recording a repeatable process. How a mold is watered is key to a processor's goal of consistency.